How to Combat Corrosion

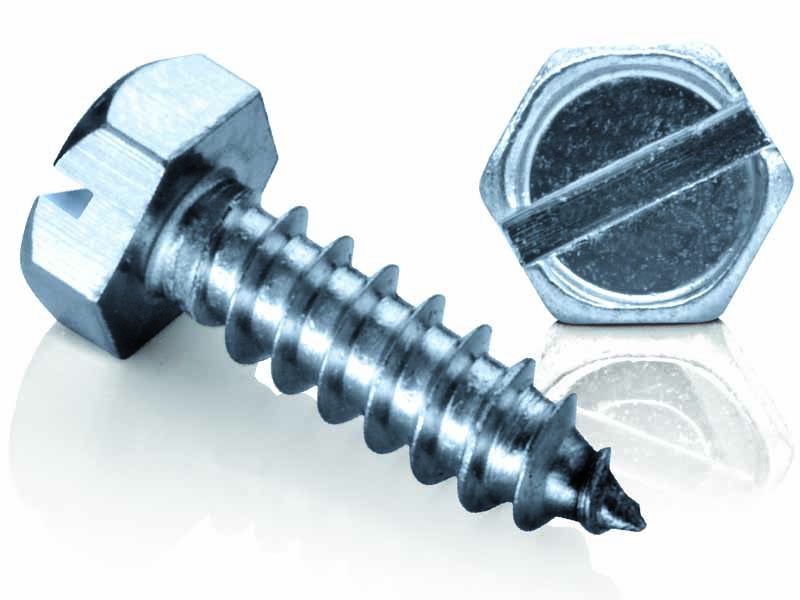

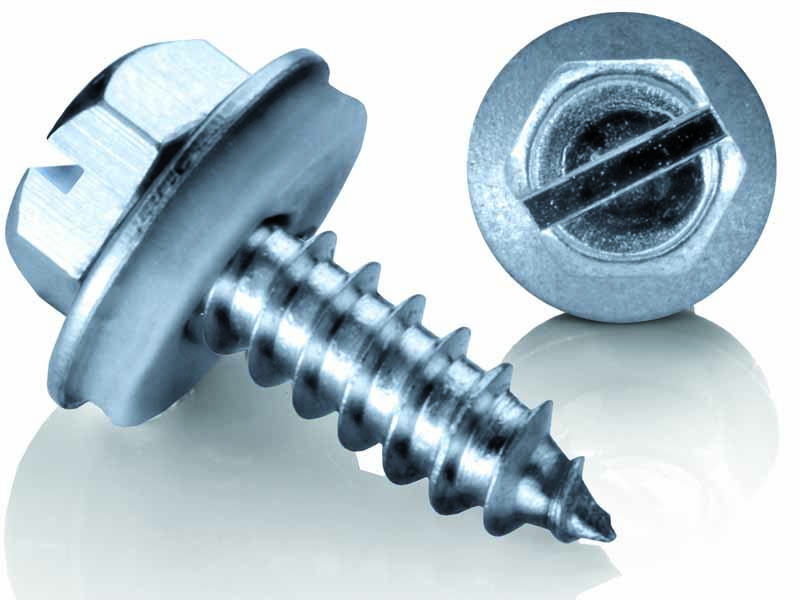

Corrosion is an ever-present threat to many metal structures, particularly those located in marine environments such as offshore oil and gas facilities. Grade 316 stainless steel screws have been widely used in the construction of such facilities and, though providing a good service life, are being superseded by tougher, longer-lasting duplex self tapping screws. BS Stainless proudly supply these essential stainless steel tapping screws.

One of the key features of duplex self tapping screws is their exceptional hardness, which prevents the delicate thread from damage. The practice of using steel screws for pre-screwing, which can lead to contamination and subsequent corrosion, employed by contractors in the past is no longer necessary as only a punched or pre-drilled hole is necessary.

Duplex 318L (variously described as UNS 31803 and 2205) combines the benefits of ferritic and austenitic steel, producing a metal with a tensile strength significantly higher than that of standard stainless steel. Composed mostly of iron, duplex also includes a high proportion of chromium (22%) with added nickel and molybdenum (5% and 3% respectively).

Other features and benefits of remarkable duplex self tapping screws include:

Increased protection against corrosion – perfect for tough marine and offshore environments where protection is needed the most in the salty, corrosive waters

Life-cycle costing is dramatically reduced, easily covering the higher price of duplex as compared to less-efficient stainless steel

Increased strength: duplex screws are a full three times harder than their grade 316 stainless steel counterparts to provide the strongest possible fastening

High PRE value: to be classed as seawater-resistant, a metal must have a PRE value higher than 33. Duplex self tapping screws from BS Stainless have a PRE value of 38.

Full range of sizes available to suit your required application, whether it is construction, metal jacketing insulation or anything in between

Complementary washers can also be supplied – choose from HNBR, Neoprene, EPDM or Polyamide